Current location:Home > Hebei Hankai 40 80 10 oil seal >

Hebei Hankai 40 80 10 oil seal

...

2025-08-14 13:27

2025-08-14 13:16

2025-08-14 12:57

2025-08-14 12:39

2025-08-14 12:23

...

2025-08-14 11:44

2025-08-14 11:11

...

2025-08-14 10:56

2025-08-14 10:49

2025-08-14 10:47

Latest articles

The sealing effectiveness of a high pressure lip seal is influenced by several factors, including the choice of elastomer, the design of the lip, the quality of the shaft surface, and the operating temperature. The elastomer must be resistant to the specific fluid or gas being sealed, while the lip design should allow for minimal friction and wear. The shaft surface must be smooth to prevent damage to the seal, and the operating temperature must fall within the acceptable range of the seal material The shaft surface must be smooth to prevent damage to the seal, and the operating temperature must fall within the acceptable range of the seal material The shaft surface must be smooth to prevent damage to the seal, and the operating temperature must fall within the acceptable range of the seal material The shaft surface must be smooth to prevent damage to the seal, and the operating temperature must fall within the acceptable range of the seal material

The shaft surface must be smooth to prevent damage to the seal, and the operating temperature must fall within the acceptable range of the seal material The shaft surface must be smooth to prevent damage to the seal, and the operating temperature must fall within the acceptable range of the seal material high pressure lip seal.

high pressure lip seal.

The shaft surface must be smooth to prevent damage to the seal, and the operating temperature must fall within the acceptable range of the seal material The shaft surface must be smooth to prevent damage to the seal, and the operating temperature must fall within the acceptable range of the seal material

The shaft surface must be smooth to prevent damage to the seal, and the operating temperature must fall within the acceptable range of the seal material The shaft surface must be smooth to prevent damage to the seal, and the operating temperature must fall within the acceptable range of the seal material high pressure lip seal.

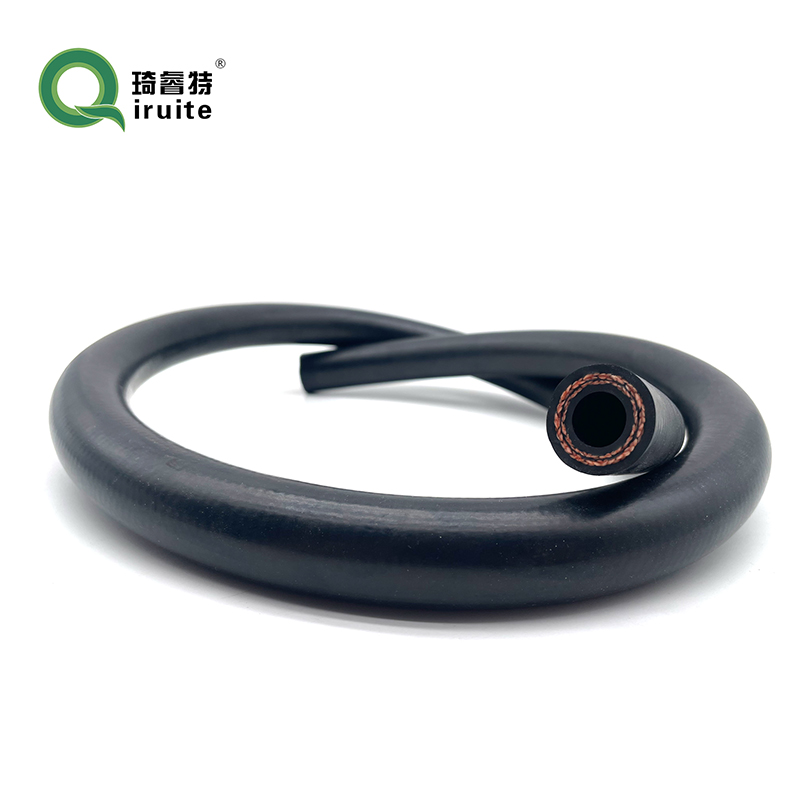

high pressure lip seal.Repairing a car's AC rubber hose is a relatively straightforward process, but it's important to have the job done by a professional to ensure that it's done correctly. The first step in repairing the hose is to diagnose the source of the problem. This may involve pressurizing the AC system to locate the leak or visually inspecting the hose for damage. Once the issue has been identified, the damaged section of the hose will need to be replaced Once the issue has been identified, the damaged section of the hose will need to be replaced Once the issue has been identified, the damaged section of the hose will need to be replaced Once the issue has been identified, the damaged section of the hose will need to be replaced

Once the issue has been identified, the damaged section of the hose will need to be replaced Once the issue has been identified, the damaged section of the hose will need to be replaced car ac rubber hose repair.

car ac rubber hose repair.

Once the issue has been identified, the damaged section of the hose will need to be replaced Once the issue has been identified, the damaged section of the hose will need to be replaced

Once the issue has been identified, the damaged section of the hose will need to be replaced Once the issue has been identified, the damaged section of the hose will need to be replaced car ac rubber hose repair.

car ac rubber hose repair.Another key advantage of 6 corrugated pipe couplings is their resistance to corrosion 6 corrugated pipe coupling. Traditional metal couplings can be susceptible to rust and corrosion, which can lead to leaks and failures over time. However, 6 corrugated pipe couplings are typically made from high-quality plastic materials that are resistant to corrosion and environmental factors. This makes them a reliable choice for applications in harsh environments, such as offshore oil rigs or chemical processing plants.

6 corrugated pipe coupling. Traditional metal couplings can be susceptible to rust and corrosion, which can lead to leaks and failures over time. However, 6 corrugated pipe couplings are typically made from high-quality plastic materials that are resistant to corrosion and environmental factors. This makes them a reliable choice for applications in harsh environments, such as offshore oil rigs or chemical processing plants.

6 corrugated pipe coupling. Traditional metal couplings can be susceptible to rust and corrosion, which can lead to leaks and failures over time. However, 6 corrugated pipe couplings are typically made from high-quality plastic materials that are resistant to corrosion and environmental factors. This makes them a reliable choice for applications in harsh environments, such as offshore oil rigs or chemical processing plants.

6 corrugated pipe coupling. Traditional metal couplings can be susceptible to rust and corrosion, which can lead to leaks and failures over time. However, 6 corrugated pipe couplings are typically made from high-quality plastic materials that are resistant to corrosion and environmental factors. This makes them a reliable choice for applications in harsh environments, such as offshore oil rigs or chemical processing plants.Internal pipe couplings are also versatile in their application, as they can be used to connect pipes of different materials, sizes, and configurations. This flexibility makes them a valuable tool for pipeline construction projects where various pipe sizes and materials are used

internal pipe coupling. Additionally, internal pipe couplings are easy to install and require minimal maintenance, making them a cost-effective solution for pipeline repairs and upgrades.

internal pipe coupling. Additionally, internal pipe couplings are easy to install and require minimal maintenance, making them a cost-effective solution for pipeline repairs and upgrades.

In addition to conventional mirrors, SAE J1401 also addresses advanced technologies like electrochromic (smart) mirrors and cameras, which are becoming more prevalent in modern vehicles sae j1401 1 8. These advanced systems must meet the same performance standards as traditional mirrors, ensuring they provide reliable and consistent visibility regardless of the technology used.

sae j1401 1 8. These advanced systems must meet the same performance standards as traditional mirrors, ensuring they provide reliable and consistent visibility regardless of the technology used.

sae j1401 1 8. These advanced systems must meet the same performance standards as traditional mirrors, ensuring they provide reliable and consistent visibility regardless of the technology used.

sae j1401 1 8. These advanced systems must meet the same performance standards as traditional mirrors, ensuring they provide reliable and consistent visibility regardless of the technology used.